- About Us

About Us

ChemTech is a leading chemical manufacturing company of Pakistan providing products to various industries, including textiles, construction, paints, coating & adhesives.

- Production Facility

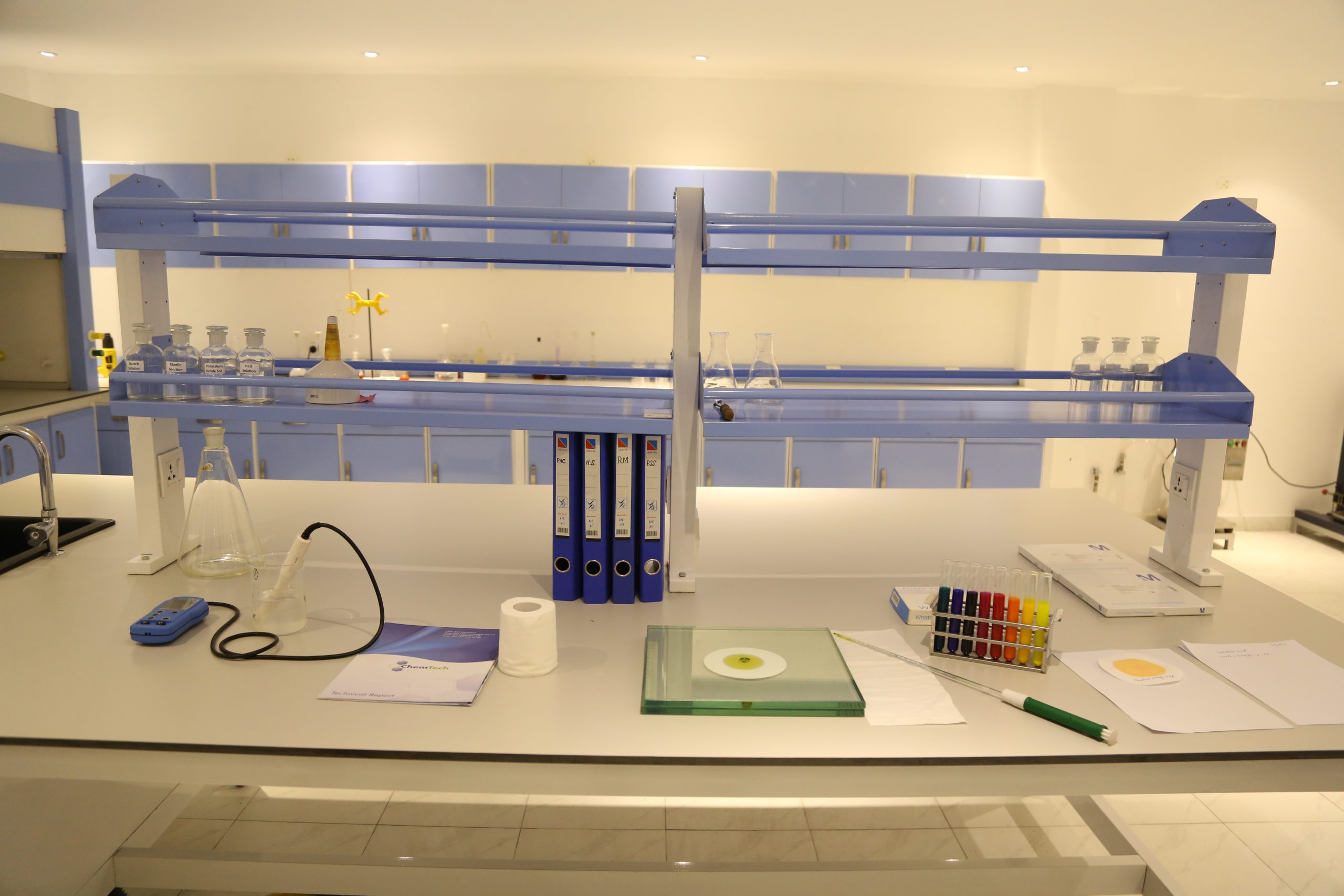

Production Facility

Chemtech International has one of the most advanced PLC Based Chemical manufacturing facility in Pakistan. The production plants have diverse capabilities for making a full spectrum of products for different industrial applications.

- Gallery

- Our Partners

- Go Green

Go Green

Sustainability is the only way forward – ChemTech is cognizant of its responsibility towards the society, its people and the environment at large. - Products

Products

With one of the most advanced production facilities in Pakistan, our products are tailor made to suite the application needs of the industry while conforming to the highest quality standards.

- Contact